Our Expertise

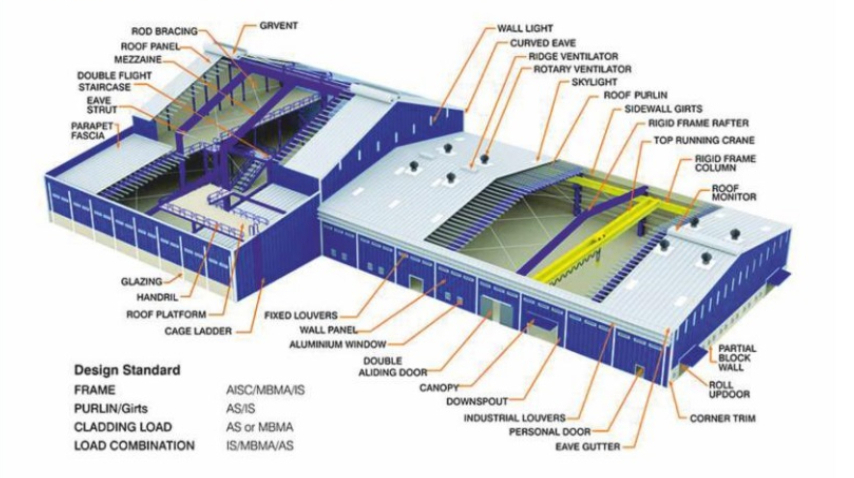

PEB 3D View

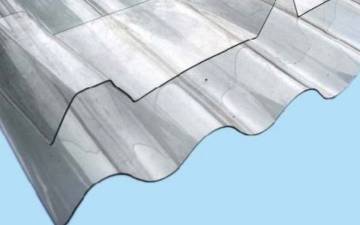

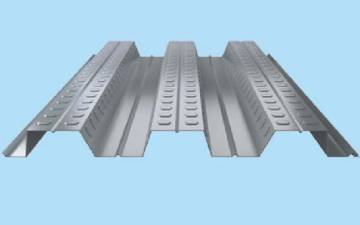

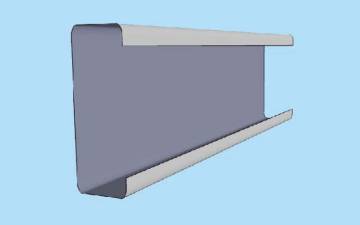

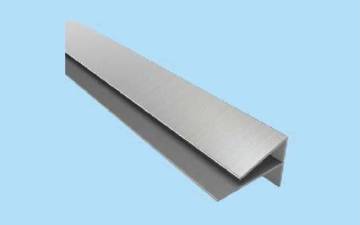

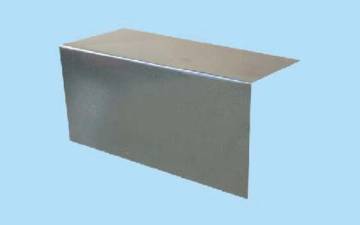

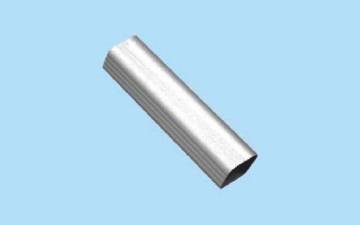

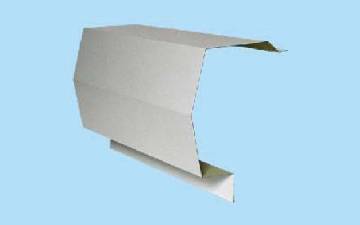

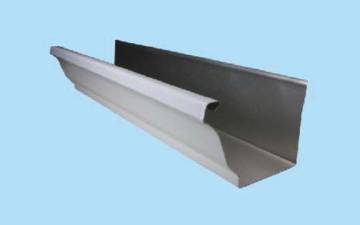

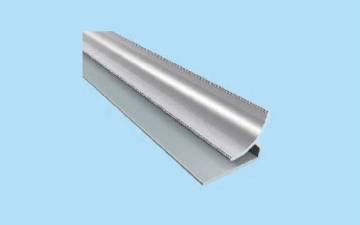

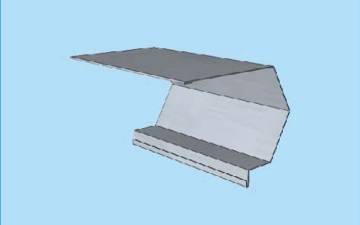

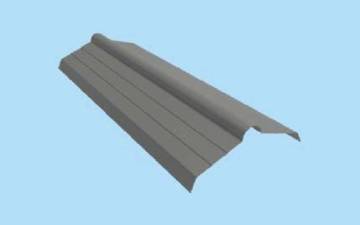

SteelFab Pre engineered buildings are and fabricated to meet client requirements and in accordance with the universal standards. A Pre engineered building consists of four important components primary members, secondary members, metal roofing wall cladding and connection fastners.

These components are so designed that they are compatible with each other. The fabrication for these components is carried out in factory under strict quality control as per detailed shop drawings. These components are transported to suite with proper markings and assembled at site as per erection drawings.

Salient Features

Uses tapered beam section concept, thus ensuring right amount of structural steel at right place. Built up sections are made from HR plats with submerged arc welding process in automatic welding machine in the factory. Uses cold formed either galvanized or non galvanized section for secondary members. Usage of metal colour coated material for sheets and cladding which are durable and aesthetically good looking. Column free building with longer spans, building with mezzanine, cranes with different functional requirement.

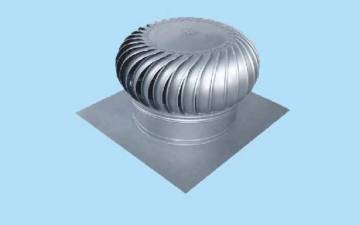

Speedy and planned execution drastically cuts down time and costs of projects. Single source responsibility from inception to completion, covering design, engineering, detailing, fabrication supply and erection. Design which provide structurally stable PEBs using universally accepted codes and guidelines. Special building components like skylights, ridge ventilators, turbo ventilators, sliding doors, windows, roof curbes etc. can be supplied and installed. Insulation to maintain temparature under control.